Every machine builder faces the same problem, how can I determine the best possible cycle time for each customers need? In order not to actually test this after the construction of the machine, a physical simulation of the machine is required. We have implemented a simple method with our partners the WEISS Group and ControlEng Corporation.

Every machine builder faces the same problem, how can I determine the best possible cycle time for each customers need? In order not to actually test this after the construction of the machine, a physical simulation of the machine is required. We have implemented a simple method with our partners the WEISS Group and ControlEng Corporation.

For the linear transfer system LS Hybrid from the WEISS Group the motor is continuously held in the optimal operating position by the movement profile overlap of the cylinder cam and servomotor. This results in both significantly shorter workpiece change times, as well as higher production output of up to 60 parts per minute, depending on process time, stroke and loading. The movement profile is optimized to reduce jerk, also ensuring extremely gentle transportation of the workpiece carriers without any jolts.

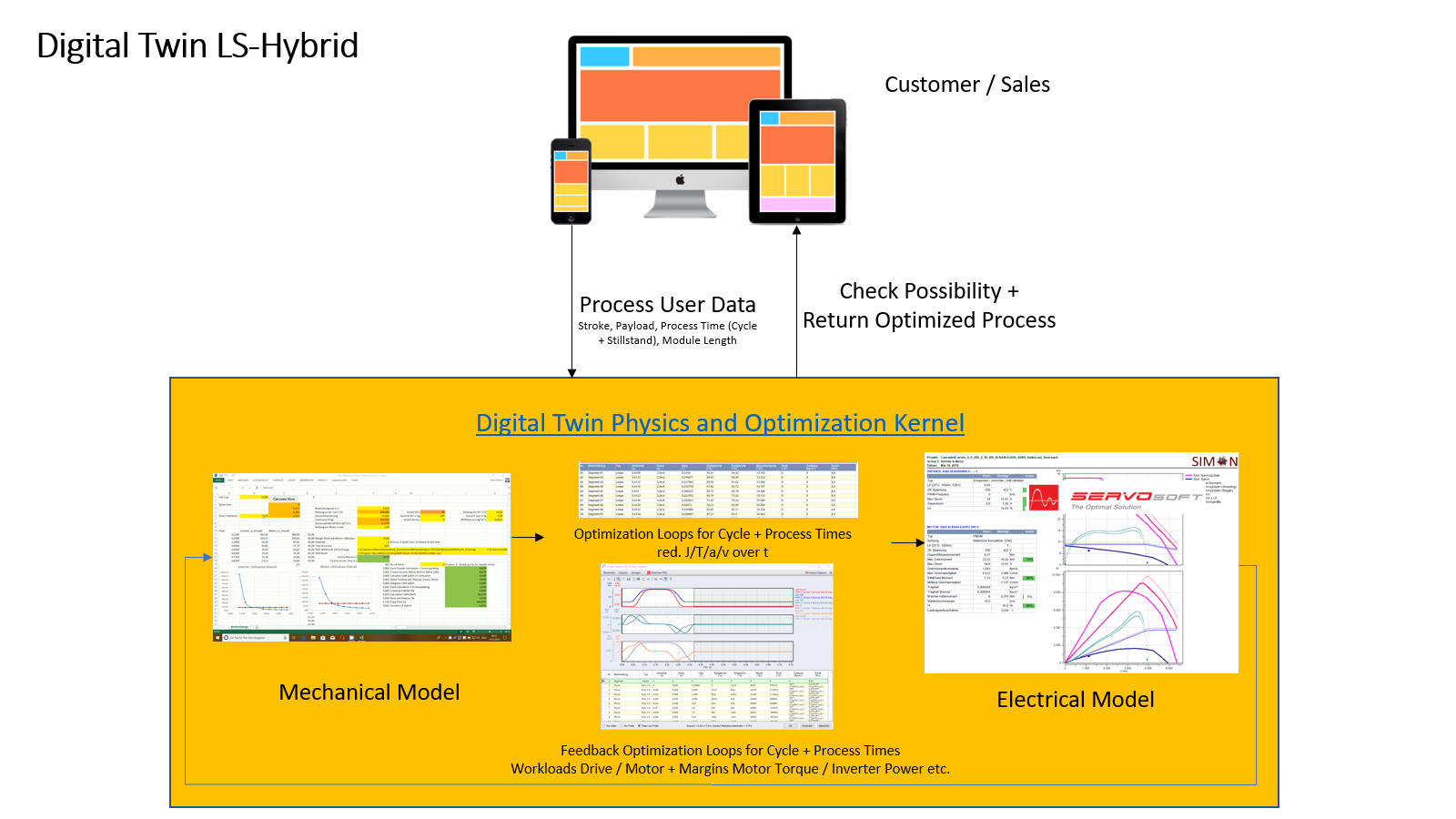

Using a special software tool, the eCam module can be configured to optimize cycle times to fit the application. The SERVOsoft® Command Line Interface Option for external optimization tools and the Optimizer PRO Auto Update feature now allows you to evaluate the machine’s physical model under different conditions. SERVOsoft® evaluates the entire powertrain in each optimization step, which specifies the mechanical model, and makes the results available so that physical simulations of the machine can easily be realized.

In addition our own software Optimize Curves, whilst interacting with SERVOsoft®, is now also capable of optimizing CAMs for cycle time regarding the complete physical model.